NO more bow tie error bands

Issue

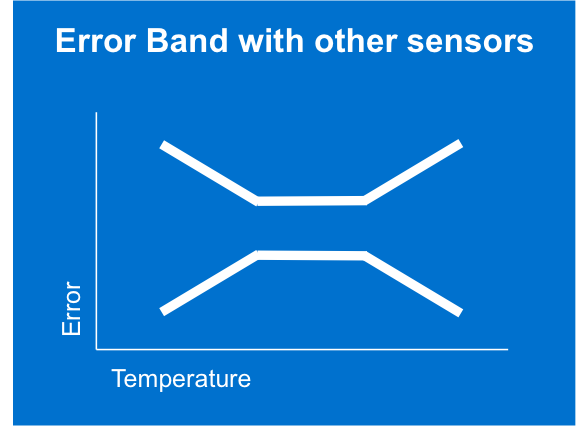

A manufacturer of engine systems was able to get accurate pressure readings (<1% error), but only within a limited temperature range (0-100°C). Once the operation exceeded this range, the pressure readings became less reliable, with error rates as high as 2%. This resulted in either false positives, giving rise to unnecessary maintenance; or false negatives, causing critical levels to go unchecked and compromising the integrity of the systems using that information.

Solution

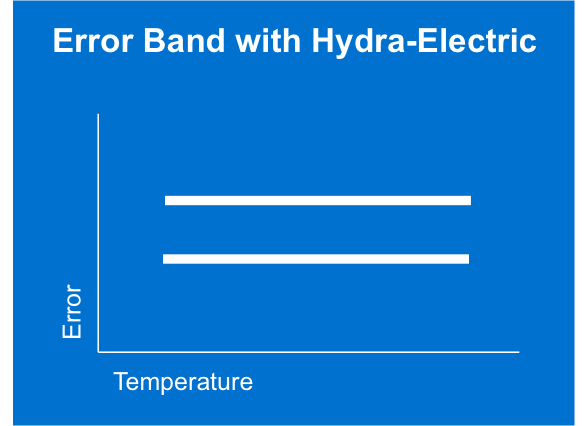

Hydra-Electric incorporated its sensor technology, which provides for a flat error band across the entire temperature range and pressure range. It should be noted that this includes hysteresis, repeatability and sensitivity. This means that not only did the manufacturer have greater confidence in the pressure readings, but also that the engineers designing the system were able to redirect their error budgets to other components of the overall system.